Let’s have a little talk about stage safety, specifically in relation to use of any kind of stage rigging, lighting or other equipment in a theater.

Note * This is not an exhaustive study but simply a “basics list.” We find most schools don’t even have the basic level of safety procedures in place.

When no one is monitoring the stage systems, accidents could easily happen and most of them are avoidable. As we visit schools to review their systems, we often discover unsafe conditions which have not been addressed and that no documentation has been created to let anyone using the stage know that a dangerous situation exists. That is never a good idea.

Start With Stage Changeovers

There should be procedures in place, with sign-offs, indicating that people have checked the status of their contribution to the stage before a show starts. People should not be randomly building sets, attaching lights, adding microphone cables, lighting cables and the like without certifying that they have first done a proper, coordinated safety check. That check needs to indicate nothing is snagging, everything is attached with proper load-rated hardware and that everything is in balance. This must be a written document, accessible to all on stage. It is imperative that anyone using the stage review this safety checklist first, prior to use.

Failing to maintain this documentation is like loaning a car to someone without telling them the brakes don’t really work so don’t stop suddenly. “Oh, and the gas gauge is broken and I’m pretty sure that the headlights don’t work.”

Stage Checklist

There should also be a form that gets logged and signed off at the end of a performance or rehearsal that indicates the condition of all stage systems.

A sample basic checklist:

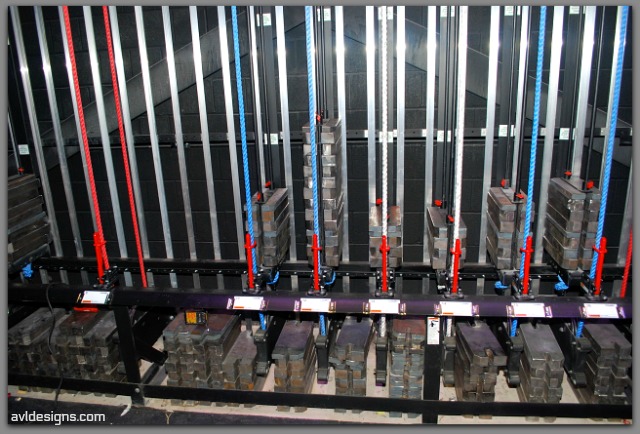

- All rope locks are engaged.

- All of the battens are properly counterbalanced.

- All battens are free from any tangled wiring or items that could impact adjacent battens.

- All lighting circuits are plugged and checked.

- All fixtures that are assigned to the show plot still work.

- All fixtures have safety cables.

- No defective wiring was found.

- There are no stage weights or anything in the locking rail that could cause problems.

- There are no trip hazards on stage

- Etc…… There are a multitude of things that should be on a sign off sheet depending on the show, venue, and special conditions.

Where a checklist alone does not suffice to indicate a safety hazard, you may also need to rope off, lock, or mark safety hazards that can’t be corrected immediately.

Safety Procedural Manual

There should be a Safety Procedural Manual for every stage. Some really good ones are available online for review. Maintaining stage safety protocols is not just a matter of making a checklist of two or three things. There are pages of checklists items that should be followed every time you change anything for show, or plan and build a show.

Define Your Team

You should also make a list of authorized personnel. Not just anybody should be able to go up on stage and perform work or run rigging systems.

If you can’t do the math to figure out the load on a batten, then you shouldn’t be allowed to touch it.

If you can’t walk up to an arbor and by a quick visual and manual inspection of the operating lines determine whether the set is in-balance or out of balance, then you shouldn’t be opening a rope lock at all.

These procedures should be in the training manual. People who have been trained should be certified by the school. Letting just anybody do anything on a stage is a recipe for trouble.

Let’s look at an example of what can happen.

You walk in and need a curtain that is flown out to be moved down towards the stage. The person who used the stage last, for some bizarre reason removed a bunch of counterweights from the curtain set arbor after it was up. That arbor is light and the curtain is heavy. You don’t know enough to recognize what has happened, so you go ahead and release the rope lock causing the curtain to come crashing down towards the stage.

There are a couple of possible outcomes this un-safe scenario may produce. In the case of a stage curtain, when some of the weight of the curtain lands on the stage, it slows down. If you’re lucky it stops before the batten it’s attached to hits anybody in the head. But, sadly, things could go the another way and it will injure somebody.

Lack of safety procedures and not insisting upon sign-offs puts people in physical jeopardy. Sign-offs basically say “Hey, show’s over. I checked all of the sets, everything’s in balance [i.e. safe] so that when you release the rope lock, nothing will start moving much by itself.” Insisting on official sign-offs makes it safer for non-skilled people to use the stage.

It is still not a good idea to have non-skilled people working the stage but, at least, it is safer with a checklist.

What if there is an electric cable that is frayed, a light was flickering, or the sound system was making a humming noise that it never made before? Log It. There must be a reporting procedure so that when anything like that is found, it will be logged and communicated in writing to someone who can check into maintenance.

Note: Procedural manuals are also needed but that is another topic. How sets are built, use of paints, special effects, power tools, fall protection, use of ladders, electrical safety, issues with strobes, lasers, etc…. will need to be in your procedural manual.

Here is a well-thought-out manual by Southern Oregon University, available for you to read (not plagiarize): Sample Stage Safety Manual

Stage Rigging Inspections

You must have inspections on a regular basis by qualified professionals. These inspections will identify where there are issues and other problems that a general checklist cannot address. ESTA and ANSI standards require inspections of counterweight manual and motorized rigging that need to be performed annually and or biannually. On motorized rigging and stage lifts, the inspectors have to be versed in the specific system, general knowledge does not suffice.

If these inspections are not being done, you’ve now left your people “using a car with bad brakes.”

Copyright AVLDesignsInc 2020