When it comes to acoustics, it’s quite common for us to get a phone call when something has gone wrong. It seems like 9 times out of 10 somebody has proceeded on a project, and they have taken a direction — they have “done some things” — and now the end-user is not happy. Whether it is a performing art space, or music space or an industrial application, when the complaints start coming, that’s when we get hired.  To be honest, it’s really the wrong way to go about doing things. What should be happening is they should hire an acoustical consultant first, before they design the project. But in a lot of projects the end-users are not speaking up. They never say, “Oh by the way, I’m really concerned about sound.” Or “I’m really concerned about this or really concerned about that” so the architects and engineers don’t even think about what the changes of finishes and dimensions may do to the sound in those areas until it is either too late or almost too late.

To be honest, it’s really the wrong way to go about doing things. What should be happening is they should hire an acoustical consultant first, before they design the project. But in a lot of projects the end-users are not speaking up. They never say, “Oh by the way, I’m really concerned about sound.” Or “I’m really concerned about this or really concerned about that” so the architects and engineers don’t even think about what the changes of finishes and dimensions may do to the sound in those areas until it is either too late or almost too late.

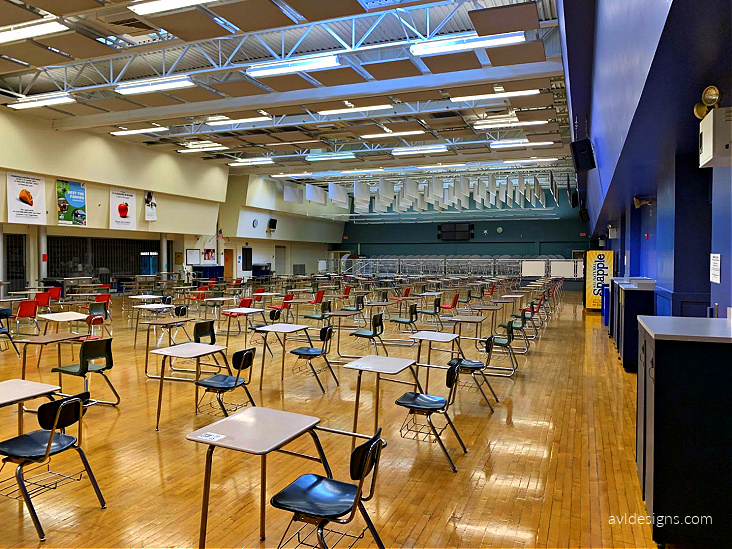

Let’s talk about one situation that came up very recently. We got a call from an architectural/engineering firm about an auditorium that they were “renovating” “acoustically.” I put those words in quotes separately because the meaning of each can be obscure, to say the least. It was a conference call and, during this call, somebody asked if did they did the right things? So, I asked “what is the reason you’re doing this?” Their answer was “well, the room needed to be updated.”

Next, I asked them “what about the people who use the room? Do they like the way it sounds now?” We had visited it and It’s a nice, kind of average auditorium. It has absorption on the back of the room, including a cavity that goes out the room to an outer lobby in some locations to provide some added resonance out there. The sidewalls have some absorptive panels that are on standoffs from the wall to absorb lower frequencies than they would without it.

Listen! The actual users already liked the way the room sounds!

No one ever asked the end users, do they like the room? Well, it turns out in this case they do. The plans in the works were about to change all that. This is a drywall room with a drywall ceiling, which means low frequencies are being absorbed through the drywall. The music department of this particular school likes the space. The changes that they were about to make are so radical that we were compelled to draw their attention to the drawbacks. We said, “look, you really need to analyze this before proceeding.” We do our analyses by conducting field testing. We take the existing condition, which the end-users like, and we compare that to what the estimate in a model says it will be once the proposed changes are implemented. I believe, for the sake of everyone concerned, this is the prudent way of going about things. The “look before you leap” method.

Before Making Radical Changes, First Test It Out.

We suggested that we test, report and evaluate just what they would have, if they applied the changes they wanted to make. The plan was to treat the whole back of the room. They were going to take the perforated section that absorbs all sorts of energy, and they were going to make that solid. Next, they were going to curve it. Plus, they were going to cover it in ceramic tile “because it is durable.”

But not everything that seems like a good idea is a good idea. The plan was to have ceramic tile up to about 12 feet off the ground. Then above 12 feet, they were going to place acoustic diffusion using a product that has a relatively non-absorptive characteristic. It is a great diffuser, but diffusers should be placed down low on the wall, where your ears are. Putting 12 feet of ceramic tile below and all this diffusion up above is at an elevation where nobody is going to get the benefit. It will diffuse some sound and that will then bounce off the ceiling. And all of this is going to make the room far bass heavier than it is now. It’s also going to add strident high frequencies because, believe it or not, drywall still has a small absorption coefficient even up at high frequencies. So suddenly you are going to have this room with a twang to it and diffusion occurs where no one sits. And this giant curve to be added to the back of the room will create a major echo back to the stage. So, we are truly hoping they hire us to solve this problem before it occurs.

Before making decisions, ask the end-users what they hear!

One of our ways of dealing with this is to send the end-users a questionnaire with guided questions to get a sense of what they hear. It is hard when you don’t get to meet with the people and hear a live performance where you all can talk about it and say, “Hey, what are you hearing?” But we do our best. What do you think about this? What do you think about that? And then we’re hopefully going to guide them to make changes that are in line with what the end user wants acoustically the result they’re looking for as opposed to a visual that somebody thought would be cool. Sometime manufacturers reps get involved in this process and they will say, “Hey, here’s a cool looking product.” And they will make a lot of money if you buy it. And then they will put it all over the room and they don’t think about where it goes. And the inevitable complaints shall come.

The general rule of thumb for auditoriums is “down low” for reflective and diffusive surfaces. Where they get placed depends on more than just the room. It also gets placed based on the sound system and where speakers are bouncing off the walls, things of that nature. Typically, speakers go way up high in a room. If there’s anything up there, it’s absorption. Usually, it is relatively thin absorption to pick up high frequencies before they hit the ceilings and create kind of this weird after-ring-sheen that a lot of rooms have. So that’s kind of a general course, but what we’re hoping we’ll be doing is modeling it, finding a correction before it gets built. But my advice here is if you’re going to change a room, talk to the people who use it. If they say, “look, we want this room to be X” or “we’re happy with this room” you better be sure that what you are doing doesn’t change the way the room sounds. If you want to change it visually, that’s great. A coat of paint can do that. But don’t start putting in materials with an unknown characteristic.

By the way, the YouTube version of this is a fireside chat: How To Avoid Doing Bad Acoustics – A Fireside Chat with Seth Waltz We have a lot of other videos on various subjects. Please watch and subscribe to get the most current videos.

/

Copyright AVL Designs Inc. 2023+

Every stage lighting fixture in the room has been replaced with LED color changing fixtures from Electronic Theater Controls, High End Systems and Varulite. Every fixture is now on relay-controlled power, which automatically shuts them off when they are not in use, thus extending their lives.

Every stage lighting fixture in the room has been replaced with LED color changing fixtures from Electronic Theater Controls, High End Systems and Varulite. Every fixture is now on relay-controlled power, which automatically shuts them off when they are not in use, thus extending their lives.

To be honest, it’s really the wrong way to go about doing things. What should be happening is they should hire an acoustical consultant first, before they design the project. But in a lot of projects the end-users are not speaking up. They never say, “Oh by the way, I’m really concerned about sound.” Or “I’m really concerned about this or really concerned about that” so the architects and engineers don’t even think about what the changes of finishes and dimensions may do to the sound in those areas until it is either too late or almost too late.

To be honest, it’s really the wrong way to go about doing things. What should be happening is they should hire an acoustical consultant first, before they design the project. But in a lot of projects the end-users are not speaking up. They never say, “Oh by the way, I’m really concerned about sound.” Or “I’m really concerned about this or really concerned about that” so the architects and engineers don’t even think about what the changes of finishes and dimensions may do to the sound in those areas until it is either too late or almost too late.