Sound in cafeterias can be harsh. A primary reason for that is that cafeterias are difficult places to design acoustically but why is that?

Well, first, since surfaces must be easily cleaned, so some acoustical treatments cannot be used where they need to be placed. You can’t wash them. So, with that reality plus the sometimes-loud inhabitants of a cafeteria, there is the potential for a lot of noise. We get calls all the time with noise complaints about cafeterias. In most cases, design attempts were made to correct the problem, but the attempts were not well thought-out.

NRC RATING

Sound is absorbed by specific materials. Lab tests provide an idea of how well materials absorb sound know as NRC* ratings. (*noise reduction coefficient) NRC, however, does not tell the whole story on how well a product will perform in a given environment. The way sound impacts an absorbing surface affects the way it performs. When sound strikes at a severe angle the absorption is reduced, and frequency response affected.

Additionally, where absorption is located is crucial in controlling apparent volume. Voices bouncing off parallel walls causes an effect known as “flutter echo.” This repetitive echo makes rooms sound harsh. You cannot control this by placing materials up at higher elevations in the room. It doesn’t work.

FREQUENCY BALANCE

The human ear is very sensitive to certain frequency ranges. If a room has an improper frequency balance it can sound offensive no matter what reverberation level is actually present.

LOUDNESS

There are two primary issues that make a cafeteria sound loud

- Reverberation (Sound hanging around in the room over time.)

- Frequency balance (The tone of the room: boomy, tinny etc.)

WHY CEILINGS DON’T FIX IT

As cafeteria ceilings are out of the reach of food, (that is except for the cafeterias with gravy-soaked drinking straw wrappers stuck to the ceilings.) the ceiling is often looked to as the first line of defense.17

The ceiling can be used to control reverberation as well as to help balance the frequency response of the room. Some ceiling tiles, though, absorb the wrong frequency ranges in relation to the other materials that are present in the room. Better tiles have a more even spectral performance. But the ceiling alone really won’t fix the loudness. It is simply a first line of defense.

INVERSE SQUARE LAW

Looking at reverberation only, if you need to reduce the reverberation by an amount that most people would hear that requires a doubling of the amount of absorption. If you already did the ceiling, then where do you come up with that amount of surface area? It’s usually not possible.

When panels are placed on the walls, they can perceptually make the room much better, even though the overall reverb time may not shift dramatically. Carefully integrated acoustic absorption on the walls, in the ear-height range on one or two walls, can do a lot depending on all other factors.

HAVE IT MODELED

Acoustic models can predict many factors including reverb, sound levels, flutter echoes and frequency balance. Controlling the noise in a cafeteria may seem simple, but it is still worth modeling.

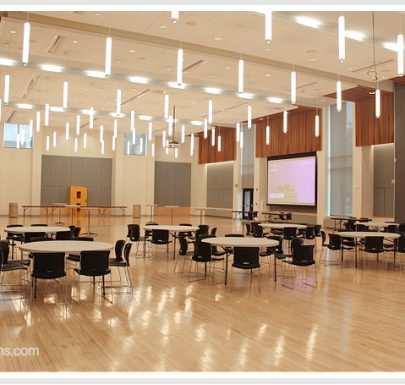

Note: all three of the images are new cafeterias; acoustical designs by AVL Designs Inc.

/

Copyright AVLDesignsInc 2021+